At the workshop entrance of Guangdong Chuang Xing Precision Fabrication Co., Ltd. (Chuang Xing), a sheet metal fabricator based in Foshan city of Guangdong province, there is a large central control screen updating production progress, monitoring equipment operation, and demonstrating order completion rate.

(Photo/Lydia Liu)

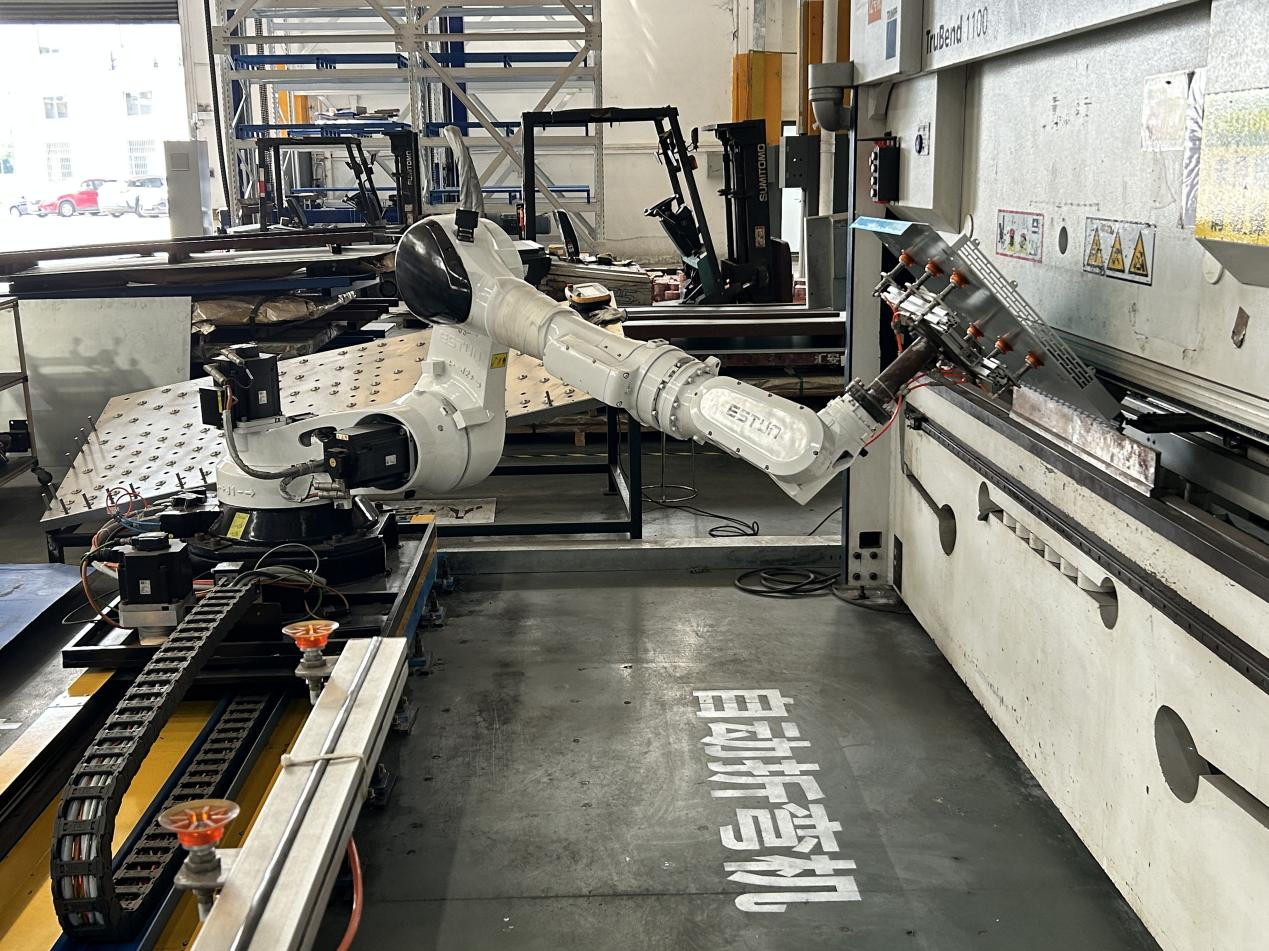

Beside the screen is the company's intelligent storage area, where mechanical arms automatically pick up and send materials to the corresponding machine. Workers then process the materials according to the drawings transmitted to the screen.

(Photo/Lydia Liu)

Through the digital transformation, Chuang Xing has grown into a leading enterprise among the cross-industry non-standard sheet metal fabricators within 20 years from a small factory with a staff of merely over 10 people and has been designated as a state-level "little giant" firm.

Chuang Xing is now taking advantage of its experience of digital transformation and dedicated to providing other traditional enterprises with products and solutions for digital transformation and upgrading.

According to China's Ministry of Industry and Information Technology, "little giant”"companies refer to leading small and medium-sized enterprises (SMEs) that specialize in niche sectors, including next-generation technologies, high-end equipment manufacturing, new energy, new materials, and biopharmacy, command a high market share, and boast strong innovative capacity and core technologies.

Guangdong KEDA Hydraulic Technology Co., Ltd. (KEDA Hydraulic) is another "little giant”"firm based in Foshan, which produces high-pressure piston pumps and high-speed motors and provides technical solutions for customers worldwide.

Yang Jun, KEDA Hydraulic's chairman of the board, told a media corp on September 20 that with the policy and financial support of Guangdong government, the company has accelerated its digital transformation in the past two years, and now its workshop has achieved full coverage of 5G and a comprehensive reconstruction of the production process.

"KEDA Hydraulichas saved 40 percent of energy consumption through digital transformation, and the output value per capita has increased by more than 60 percent," Yang noted.

The smart assembly line of Guangdong KEDA Hydraulic Technology Co., Ltd.. (Photo provided to GDToday)

To cultivate more talents for smart manufacturing companies, Guangdong Huibo Robotics Technology Co., Ltd. (Huibo Robotics), a "little giant" firm focusing on both robotics manufacturing and talent training, established a training school in 2017 in a bid to address the talent shortage in the operation and maintenance, system installation and commissioning, and system integration of robotics and intelligent equipment.

Trainees take a certification examination at Guangdong Huibo Robotics Technology Co., Ltd.. (Photo provided to GDToday)

Lin Zeqin, assistant to the general manager of Huibo Robotics, elaborated that the company's training courses are close to the needs of smart manufacturing enterprises who have been asking Huibo Robotics for targeted training of talents.

The company has so far cooperated with more than 1000 vocational schools and over 300 universities, training more than 3000 teachers and thousands of technicians.